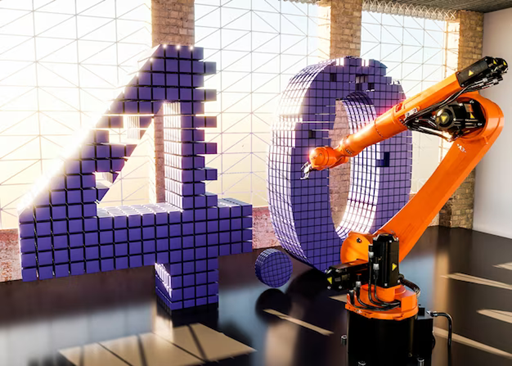

Learn how Industry 4.0 can transform asset management, reduce costs, and increase efficiency in maintenance.

Industry 4.0 is a concept that originated in Germany to describe the fourth industrial revolution, characterized by the integration of advanced technologies in all production processes. This digital transformation has brought significant benefits to companies, including in asset maintenance.

With the adoption of new technologies and strategies, asset maintenance can be optimized, resulting in greater efficiency, productivity, and cost reduction.

In this article, we will explore how Industry 4.0 can be applied to asset management and what the advantages of this approach are.

What are the concepts of Industry 4.0 and how do they benefit asset maintenance?

Industry 4.0 is a concept that involves the digital transformation of companies and the use of advanced technologies to optimize processes and increase production efficiency.

One of the key concepts of Industry 4.0 in asset management is the Internet of Things (IoT). With IoT, it is possible to connect equipment and sensors to management systems, allowing real-time monitoring and precise data collection on asset performance.

This data is analyzed by Artificial Intelligence (AI) and Machine Learning (ML) algorithms, which provide valuable insights for decision-making.

Another important concept is Big Data Analytics, which involves collecting and analyzing large volumes of data to identify patterns and trends. With this analysis, it is possible to anticipate problems and perform preventive maintenance, avoiding failures and unplanned downtime.

In addition, process automation and the use of collaborative robots (cobots) can reduce the need for human intervention and increase safety in operations.

Augmented Reality (AR) and Virtual Reality (VR) have also gained space in asset management, allowing employee training and capacity building, as well as simulation of maintenance and repair scenarios before execution, ensuring greater efficiency and safety.

In asset maintenance, these concepts and technologies allow for more efficient, predictive, and proactive asset management, improving equipment availability, performance, and lifespan, and reducing costs and risks of failures and unplanned downtime.

How to transform asset maintenance in the company through Industry 4.0?

A company can adopt Industry 4.0 technologies in its asset maintenance operations through solutions that facilitate the management of production systems, providing greater operational and planning capacity. Some of these technologies are Big Data and Internet of Things (IoT).

In this transformation, five steps are essential:

- implement connectivity through automation in its machines;

- collect and store data generated by connected machines;

- analyze the collected data and transform it into useful information;

- apply the obtained information to improve production processes;

- integrate the entire value chain of the company with suppliers and customers.

Manusis4 is an asset management system that allows managing the life cycle of an asset (machines, equipment, vehicles, installations). It is an innovative system that combines technology, mobility, interactivity, and intelligence.

Manusis4 can help in the transformation to Industry 4.0 through Connect, whose objective is to insert the business into the Industry 4.0 era, interconnecting machines and devices with the system. Thus, all equipment data is transmitted to Manusis4 and sent to maintainers through applications.

Do you want to enter Industry 4.0 to transform your asset maintenance? Then, request a Manusis4 demonstration and discover it now!

Leave A Comment