DIGITAL TWIN

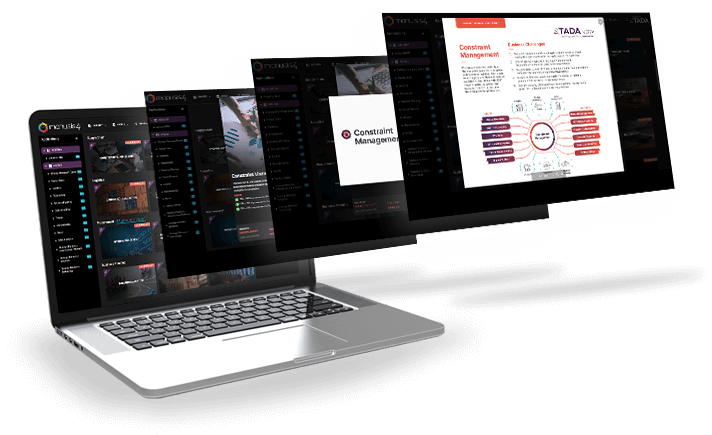

Manusis4 is the exclusive representative of the North American Tada Now – a company with more than 25 years in the market and annual revenues around US$40 million, specialized in building digital twins to control supply chains.

Tada Now builds a digital twin for every process, product, part, persona and supplier in the supply chain, connecting them in a network and linking them to a data fabric. Instead of replacing existing systems, Tada Now creates a system integrated into a network that updates itself, making a compilation of all data already existing in this company’s system.

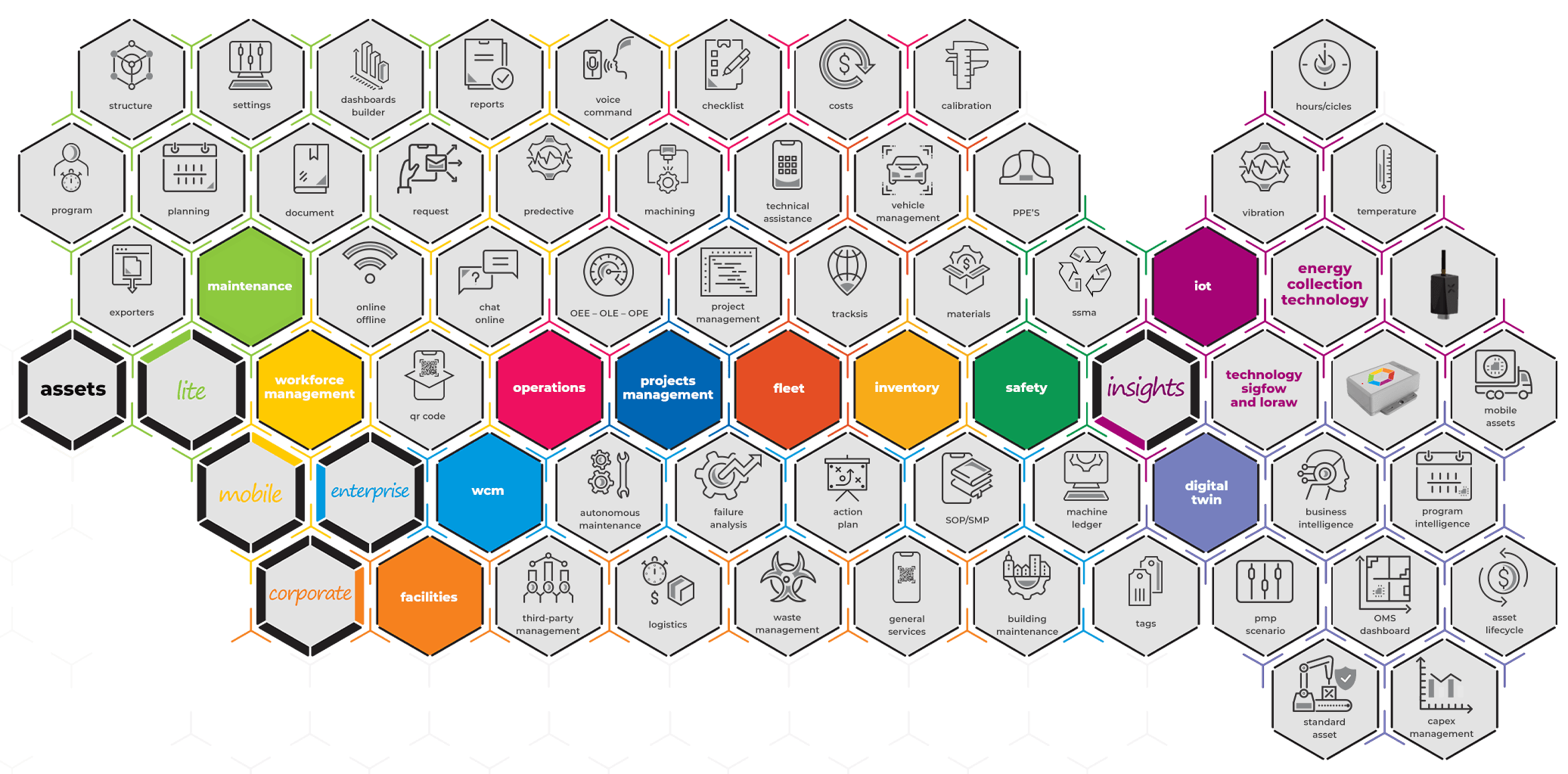

In addition, the analytical reporting and collaboration tools needed to synchronize action planning between personas are created. These workbenches are released to users using a unique, easily accessible platform. All this takes us to another dimension: Manusis4 ceases to be an asset management software and becomes a platform for asset lifecycle management, with Internet of Things (IoT), Digital Twins and Artificial Intelligence solutions (THERE).

With this, Manusis4 will be able to offer the market and its current customers a fully integrated strategic, tactical and operational vision, considering the various aspects that orbit an asset, such as: utilities, energy consumption, maintenance, operation, projects, logistics, supply chain, spare parts, people, costs and performance.

EXCLUSIVE TECHNOLOGY

DIGITAL TWINS

Through this strategic alliance, today Tada and Manusis4 have a hub of TADA solutions that can be accessed by visiting the link: TADA|Manusis4, TADA|Manusis4, an app store for all companies, regardless of sectors and challenges.

Furthermore, the TADA platform is already integrated into the Manusis4 platform:

VIRTUAL TASK SCHEDULING ASSISTANT

In day-to-day asset management, planning and scheduling activities are essential for achieving maximum performance from your machines and equipment. Defining “what” and “how” to do – planning – involves analyzing intervention history, manufacturer manuals, and the expertise of specialized teams in operational engineering, maintenance, and reliability to design preventive maintenance plans and predictive maintenance actions that aim for maximum availability and maintainability of a machine, operating within reliability standards for which it was designed.

After this planning stage, it is important to define “who” and “when” for the execution of these plans, the famous scheduling of daily activities. This is as important as the planning stage because it is necessary to assign the maintainer with the appropriate skills and determine the best timing for the intervention to minimize impacts on processes and maximize the asset’s lifespan.

In today’s technology-driven environment – machine learning and AI – it is already possible to automate routine tasks in companies. And now, in Manusis4 Insights, our advanced cognitive technology solution, you can create your own Virtual Maintenance Scheduler!

Through a parameterization process that combines maintenance plans, data history, opening horizons, technician skills, and service requests, our Virtual Maintenance Scheduler analyzes the data, automatically opens a work order, and sends it to the maintenance technician’s smartphone or maintenance team, who will use Manusis Mobile to execute the order and record all information in the platform for feedback purposes.

In a conventional maintenance setting, depending on the asset management platform used – a CMMS, EAM, or general maintenance module – a maintenance scheduler is required to manage 40 to 50 work orders per day, dedicated full-time to this process. A company generating 10,000 orders per month for scheduling would need 10-15 schedulers. Imagine having the Manusis4 Insights Virtual Maintenance Scheduler performing scheduling actions 24 hours a day and redirecting this team of professionals to the areas of planning, reliability, and asset management intelligence, to further analyze data and promote improvement actions!

That’s right, the future has already arrived in asset management, and we can help you with this digital transformation.

VIRTUAL TASK SCHEDULING ASSISTANT

In day-to-day asset management, planning and scheduling activities are essential for achieving maximum performance from your machines and equipment. Defining “what” and “how” to do – planning – involves analyzing intervention history, manufacturer manuals, and the expertise of specialized teams in operational engineering, maintenance, and reliability to design preventive maintenance plans and predictive maintenance actions that aim for maximum availability and maintainability of a machine, operating within reliability standards for which it was designed.

After this planning stage, it is important to define “who” and “when” for the execution of these plans, the famous scheduling of daily activities. This is as important as the planning stage because it is necessary to assign the maintainer with the appropriate skills and determine the best timing for the intervention to minimize impacts on processes and maximize the asset’s lifespan.

In today’s technology-driven environment – machine learning and AI – it is already possible to automate routine tasks in companies. And now, in Manusis4 Insights, our advanced cognitive technology solution, you can create your own Virtual Maintenance Scheduler!

Through a parameterization process that combines maintenance plans, data history, opening horizons, technician skills, and service requests, our Virtual Maintenance Scheduler analyzes the data, automatically opens a work order, and sends it to the maintenance technician’s smartphone or maintenance team, who will use Manusis Mobile to execute the order and record all information in the platform for feedback purposes.

In a conventional maintenance setting, depending on the asset management platform used – a CMMS, EAM, or general maintenance module – a maintenance scheduler is required to manage 40 to 50 work orders per day, dedicated full-time to this process. A company generating 10,000 orders per month for scheduling would need 10-15 schedulers. Imagine having the Manusis4 Insights Virtual Maintenance Scheduler performing scheduling actions 24 hours a day and redirecting this team of professionals to the areas of planning, reliability, and asset management intelligence, to further analyze data and promote improvement actions!

That’s right, the future has already arrived in asset management, and we can help you with this digital transformation.

INTELLIGENT SCHEDULING

The weekly scheduling activity is a feature available in all versions of Manusis4 that allows users to assign a work order to the most skilled maintenance technician using a drag-and-drop feature in the system interface. This functionality enables resource leveling up to their ideal saturation point. For teams with a moderate volume of maintenance orders, this is an excellent day-to-day feature.

However, for larger teams and a high volume of generated work orders, we suggest adding the Intelligent Scheduling plugin. With this plugin, you can simulate scheduling based on pre-established parameters, and once you have the ideal scenario, simply confirm the weekly schedule, and all work orders will be distributed to your maintenance technicians.

PMP SCENARIOS

In this plugin, our Digital Twin technology collects all information from preventive maintenance plans, inspection routes, and lubrication routes, providing users with a dynamic 52-week visualization that includes historical data for comparisons. It allows users to view preventive and corrective actions on the same timeline and offers simulation capabilities using parameters such as MTBF, MTTR, asset classification, material resources, labor, and costs. Through scenario simulations, this plugin helps users define the best execution scenario for plans and inspections in an optimized manner, considering costs and resources.

INTELLIGENT SCHEDULING

The weekly scheduling activity is a feature available in all versions of Manusis4 that allows users to assign a work order to the most skilled maintenance technician using a drag-and-drop feature in the system interface. This functionality enables resource leveling up to their ideal saturation point. For teams with a moderate volume of maintenance orders, this is an excellent day-to-day feature.

However, for larger teams and a high volume of generated work orders, we suggest adding the Intelligent Scheduling plugin. With this plugin, you can simulate scheduling based on pre-established parameters, and once you have the ideal scenario, simply confirm the weekly schedule, and all work orders will be distributed to your maintenance technicians.

PMP SCENARIOS

In this plugin, our Digital Twin technology collects all information from preventive maintenance plans, inspection routes, and lubrication routes, providing users with a dynamic 52-week visualization that includes historical data for comparisons. It allows users to view preventive and corrective actions on the same timeline and offers simulation capabilities using parameters such as MTBF, MTTR, asset classification, material resources, labor, and costs. Through scenario simulations, this plugin helps users define the best execution scenario for plans and inspections in an optimized manner, considering costs and resources.

WORKER ORDER DASHBOARD

This plugin is a live dashboard of work orders generated through systematic actions in Manusis4 or based on service requests from internal customers. Users can use our Digital Twin technology to teach the system the key parameters that determine the priority of one work order over another, ensuring that the dashboard is automatically updated and resources are reallocated when necessary.

ASSET LIFE CYCLE COST

One of the fundamental goals of an asset management system is to provide users with predictability of an asset’s life cycle. In this plugin, users can set a range of parameters according to their business reality and asset characteristics. Once these parameters are input, our machine learning technology provides users with information on when to reconsider the use of an existing asset and when it should be replaced to avoid significant impacts on their processes.

WORKER ORDER DASHBOARD

This plugin is a live dashboard of work orders generated through systematic actions in Manusis4 or based on service requests from internal customers. Users can use our Digital Twin technology to teach the system the key parameters that determine the priority of one work order over another, ensuring that the dashboard is automatically updated and resources are reallocated when necessary.

ASSET LIFE CYCLE COST

One of the fundamental goals of an asset management system is to provide users with predictability of an asset’s life cycle. In this plugin, users can set a range of parameters according to their business reality and asset characteristics. Once these parameters are input, our machine learning technology provides users with information on when to reconsider the use of an existing asset and when it should be replaced to avoid significant impacts on their processes.

ASSET CHAMPION

This plugin is ideal for companies with multiple units or many similar equipment. The user can define their standard asset, which is the asset with the best availability, maintainability, MTBF, MTTR, costs, among other possible parameters combined or not. Once this selection is made using AI algorithms, the system will compare the data of this asset with its counterparts, providing a detailed comparative view and suggesting actions for each pair to get closer to the standard asset.

CAPEX MANAGEMENT

This plugin is an add-on to the project module. Using Digital Twin technology, this plugin reads all project or project portfolio data and provides a summarized and detailed analysis of project indicators such as IDC (cost index) and IDP (schedule index). It creates the project’s S curve and performs trend analysis, estimating a range of probability for project delivery within the established schedule and cost.

ASSET CHAMPION

This plugin is ideal for companies with multiple units or many similar equipment. The user can define their standard asset, which is the asset with the best availability, maintainability, MTBF, MTTR, costs, among other possible parameters combined or not. Once this selection is made using AI algorithms, the system will compare the data of this asset with its counterparts, providing a detailed comparative view and suggesting actions for each pair to get closer to the standard asset.

CAPEX MANAGEMENT

This plugin is an add-on to the project module. Using Digital Twin technology, this plugin reads all project or project portfolio data and provides a summarized and detailed analysis of project indicators such as IDC (cost index) and IDP (schedule index). It creates the project’s S curve and performs trend analysis, estimating a range of probability for project delivery within the established schedule and cost.

REQUEST A DEMONSTRATION AND KNOW Manusis4

Fill out the form and receive temporary login and password to access and know the main features of MANUSIS in its various versions for 30 days.